Shipping containers are an integral part of the global economy, responsible for transporting goods and products across the world. Shipping containers are made up of various components that come together to form a highly durable, secure, and versatile transportation system. These components have been specifically designed to withstand the harsh conditions that can be encountered during transportation by sea, road, and rail.

In this article, we will take a closer look at the various components of shipping containers and their functions.

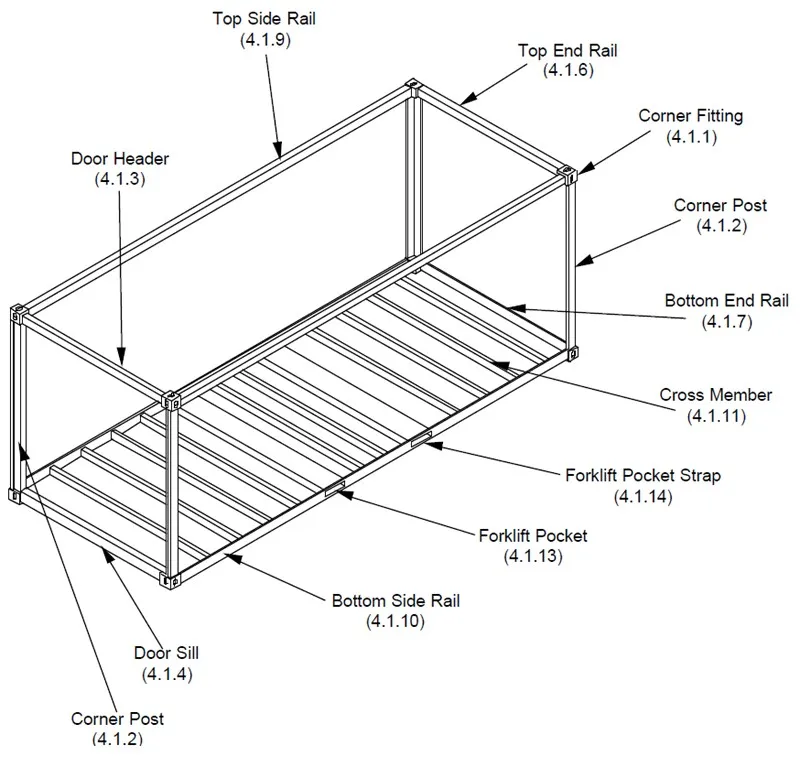

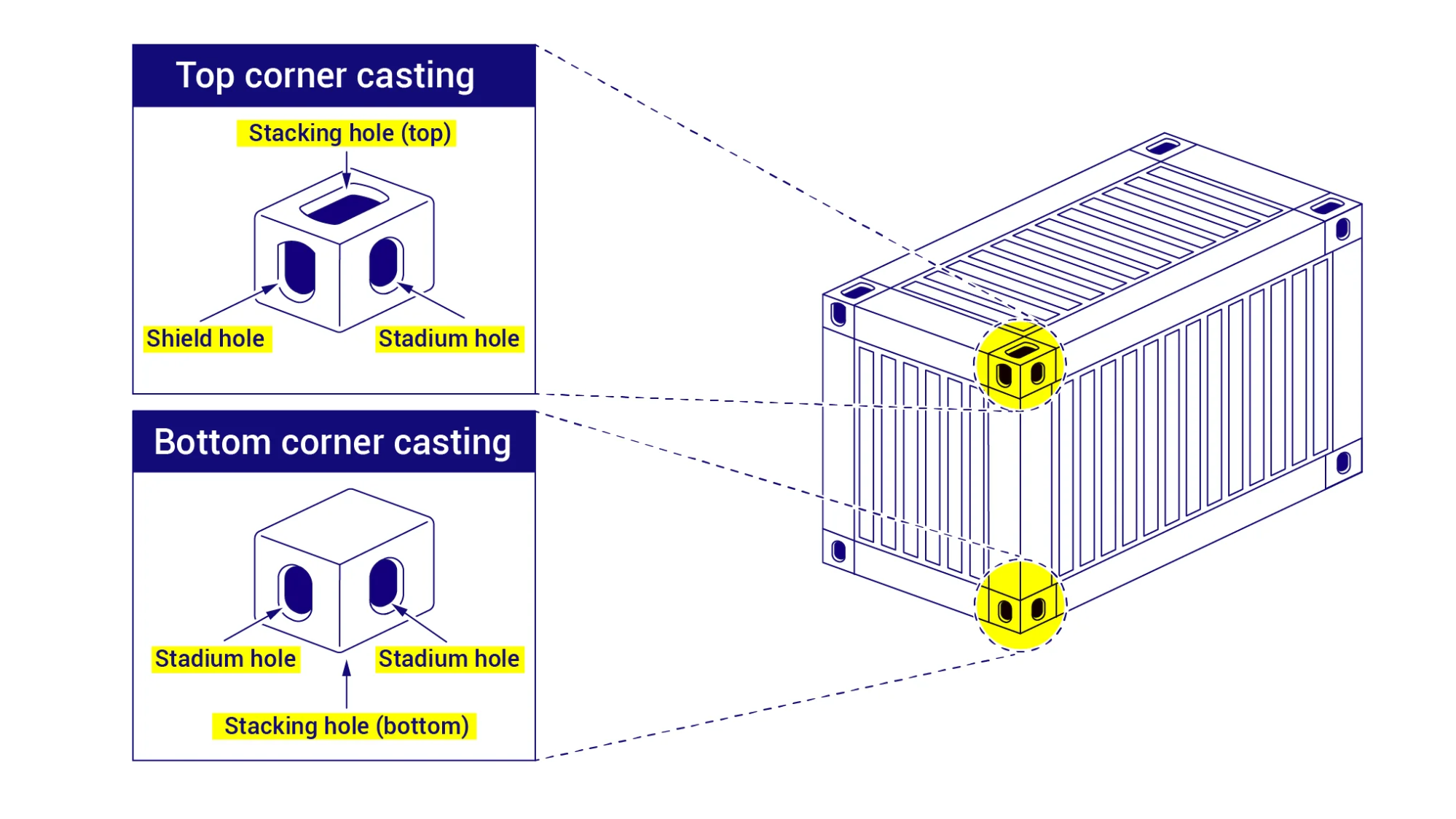

Corner Castings

The corner castings are located at the four corners of the shipping container and are used for lifting and securing the container during transportation. They are made from cast steel and are highly durable. The corner castings provide a secure and stable anchor point for lifting the container, using a crane, forklift, or other lifting equipment. They are also used to secure the container to the vessel or transportation platform, ensuring that it remains in place during transportation.

Lashing Rings

During transportation, the cargo within a container can shift and move due to the movement of the vessel. Lashing rings provide a way to anchor the cargo in place and prevent it from shifting, which could cause damage to the goods or even cause the container to tip over.

They are typically welded onto the corners of a container and provide a secure anchor point for straps or chains to be attached, which then keep the cargo in place and prevent it from shifting or falling during transport. Lashing rings are an important safety feature and are required by international shipping regulations.

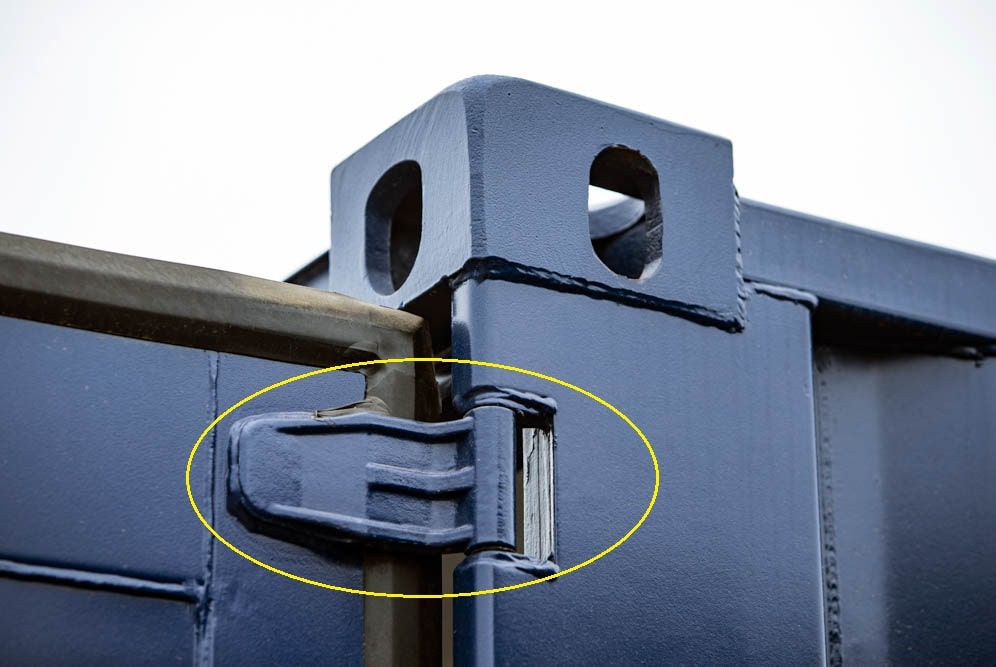

Door Hinges

The door hinges are located on the back of the shipping container and are responsible for allowing the doors to swing open and closed. The doors are hinged to the container using a heavy-duty, high-strength hinge system that can withstand the weight of the doors and the cargo that is contained within the container. The hinges are designed to be highly durable and are able to withstand the harsh conditions that can be encountered during transportation.

Locking Mechanism

The locking mechanism is an integral part of the shipping container, responsible for securing the container doors in place. The locking mechanism is located on the back of the container, between the doors. It is designed to be highly secure and can withstand attempts to force the doors open. The locking mechanism is typically made from heavy-duty steel and is able to withstand the harsh conditions that can be encountered during transportation.

Roof Panels

The roof panel is a key component of the shipping container, forming the top of the container. The roof panel is made from corten corrugated steel and is designed to be highly durable. The roof panel is also designed to be weather-resistant, ensuring that the contents of the container remain dry and free from moisture during transportation.

Side Panels/Container Wall

The side panels are another key component of the shipping container, forming the sides of the container. The side panels are made from corten corrugated steel and are designed to be highly durable. The corrugations in the steel are designed to provide strength and rigidity to the panel, ensuring that it can maintain its overall structure without needing to be thicker or heavier and withstand the harsh conditions that can be encountered during transportation. The side panels are also designed to be weather-resistant, ensuring that the contents of the container remain dry and free from moisture during transportation.

Air Vents

The vents are an important component of the shipping container, responsible for allowing air to circulate within the container. The vents are typically located on the sides of the container and are designed to prevent condensation and ensure that the contents of the container remain dry during transportation. The vents are also designed to prevent the build-up of gas within the container, ensuring that the container remains safe during transportation.

Plywood Flooring

The plywood flooring is an optional component of shipping containers that sit on top of the metal floor panels. It is typically made from hardwood plywood and is designed to protect the cargo and reduce damage during transportation. The plywood flooring provides a smooth and level surface for the cargo to rest on, protecting it from scratches and dents that can be caused by the rough metal floor panels. The plywood flooring is also designed to provide additional insulation, helping to regulate the temperature within the container and protect the cargo from extreme temperatures.

Rubber Gaskets

Rubber gaskets are an essential component of shipping containers, responsible for preventing water and air from entering the container through gaps in the panels. They are typically located around the edges of the doors and the panels and are designed to create a tight seal, ensuring that the container remains weather-resistant and airtight during transportation. The rubber gaskets are typically made from high-quality materials, such as EPDM, which can withstand the harsh conditions that can be encountered during transportation.

Forklift Pockets

The forklift pockets are located at the bottom of the shipping container and are designed to allow forklifts to lift and move the container. They are typically located in the corners of the container and are designed to be strong and durable, ensuring that the container can be safely and easily moved during transportation. The forklift pockets are made from steel and are able to withstand the weight of the container and the cargo that is contained within it.

DNV container’s parts

Pad Eye

Pad eyes are typically located on the corners and sides of a cargo container. They are usually welded onto the exterior surface of the container, providing a secure anchor point for lifting and handling equipment such as slings, chains, or hooks.

On a standard ISO shipping container, there are usually eight pad eyes located at the top corners of the container, with four on each end. Pad eyes are an important safety feature, as they help to ensure that containers are lifted and handled in a secure and controlled manner.

This feature only exists on DNV containers.

Protective bar

A protective bar for a DNV container is a type of equipment used to protect the container and its contents from damage during transportation and handling. The protective bar is typically made of steel and is designed to be mounted on the outside of the container to provide an additional layer of protection against impacts and other hazards. The bar is often used in combination with other types of equipment such as corner castings, lifting lugs, and tie-down points to secure the container and ensure its safe transportation.

The design and specifications of a protective bar for a DNV container may vary depending on the type of the container. If you are planning to modify DNV and add protective bars, it is important to consult with a qualified engineer or equipment supplier to ensure that the protective bar meets the necessary standards and is appropriate for the intended use.

Purchasing a Conex Box

In conclusion, shipping containers are made up of various components that come together to form a highly durable, secure, and versatile transportation system. These components have been specifically designed to withstand the harsh conditions that can be encountered during transportation by sea, road, and rail. Each component of the shipping container plays a critical role in ensuring the safe and efficient transportation of goods and products across the world. Understanding the various components and their functions is essential for anyone involved in the transportation and logistics industry.

Tradecorp has a wide range of customization options for shipping containers for sale. We will help you find the perfect container solution for your business or project needs. Find a variety of types and sizes of shipping containers, from standard ones to tanks, and customizable ones. We will have them ready for you at a reasonable price. Fill out the contact form on our page and we will respond to your inquiry promptly.