As it turns out, shipping container owners must know how to vent a shipping container if they’re going to use it for a long time.

Despite all their benefits, basic shipping containers are unfortunately not that known for having the best ventilation systems. Since they are enclosed in nature, they prevent air from entering or exiting to keep the cargo inside safe.

Luckily, with a few modifications, a container can have a vent system it needs for the best air circulation. Let’s see how to vent a shipping container here!

Why Vent Shipping Containers?

If you’ve ever been inside an unventilated shipping container on a hot day, you’ll know how quickly it can become a sauna.

But it’s not just heat that’s the problem. Ventilation is very important in ensuring the container’s interior remains functional and free from damage.

Heat Buildup Can Make Spaces Unusable

Heavy-duty steel is the material for building containers that soak up heat like a sponge under direct sunlight.

Inside the container, the temperature can soar, making the container unbearable to stay in. If you’re using it as a home office, workshop, or storage unit, this heat buildup can be a serious problem.

Proper ventilation allows hot air to escape and cooler air to circulate, creating a much more comfortable environment.

Condensation Can Damage Everything Inside

One of the biggest issues with sealed shipping containers is condensation.

When the steel cools down at night after a hot day, moisture in the air condenses on the interior surfaces. Over time, this condensation can drip onto your belongings, cause rust, and lead to mold growth.

As such, ventilation helps balance the temperature and reduce moisture accumulation, protecting the container and its contents.

Mold and Rust Are Expensive Problems

Without airflow, moisture can linger in the container, creating the perfect conditions for mold and mildew.

This not only damages stored goods but can also degrade the container’s structure over time. Rust weakens the steel, leading to costly repairs or replacements.

Poor Air Quality Affects Health and Productivity

If you use your container as a workspace or living area, stagnant air can lead to poor indoor air quality.

This makes the space uncomfortable and unhealthy, especially if you occupy it for extended periods. Proper ventilation ensures fresh air flows through, improving both comfort and safety.

Various Ventilation Types for Shipping Containers

With the importance of venting a shipping container, many ventilation options are available to meet different needs. Depending on your container’s specifications, one of the following options is perfect for the container.

Active Vents: Powered Airflow for Maximum Control

Active vents use electrical systems, like fans or air conditioners, to actively move air in and out of the container. These systems are perfect for spaces where precise temperature and humidity control are essential.

- Best For: Living spaces, offices, or workshops that need consistent airflow.

- How It Works: A fan-powered system draws fresh air and expels hot, stale air. Some systems include dehumidifiers for added moisture control.

- Advantages: Active vents are highly effective and offer superior control. You can adjust the airflow to suit your needs, making them perfect for extreme climates.

- Drawbacks: They require electricity, making them less practical for off-grid setups. Initial costs can also be higher compared to passive systems.

If you’re converting a container into a full-time residence, active ventilation is worth the investment for year-round comfort.

Passive Vents: Affordable and Reliable

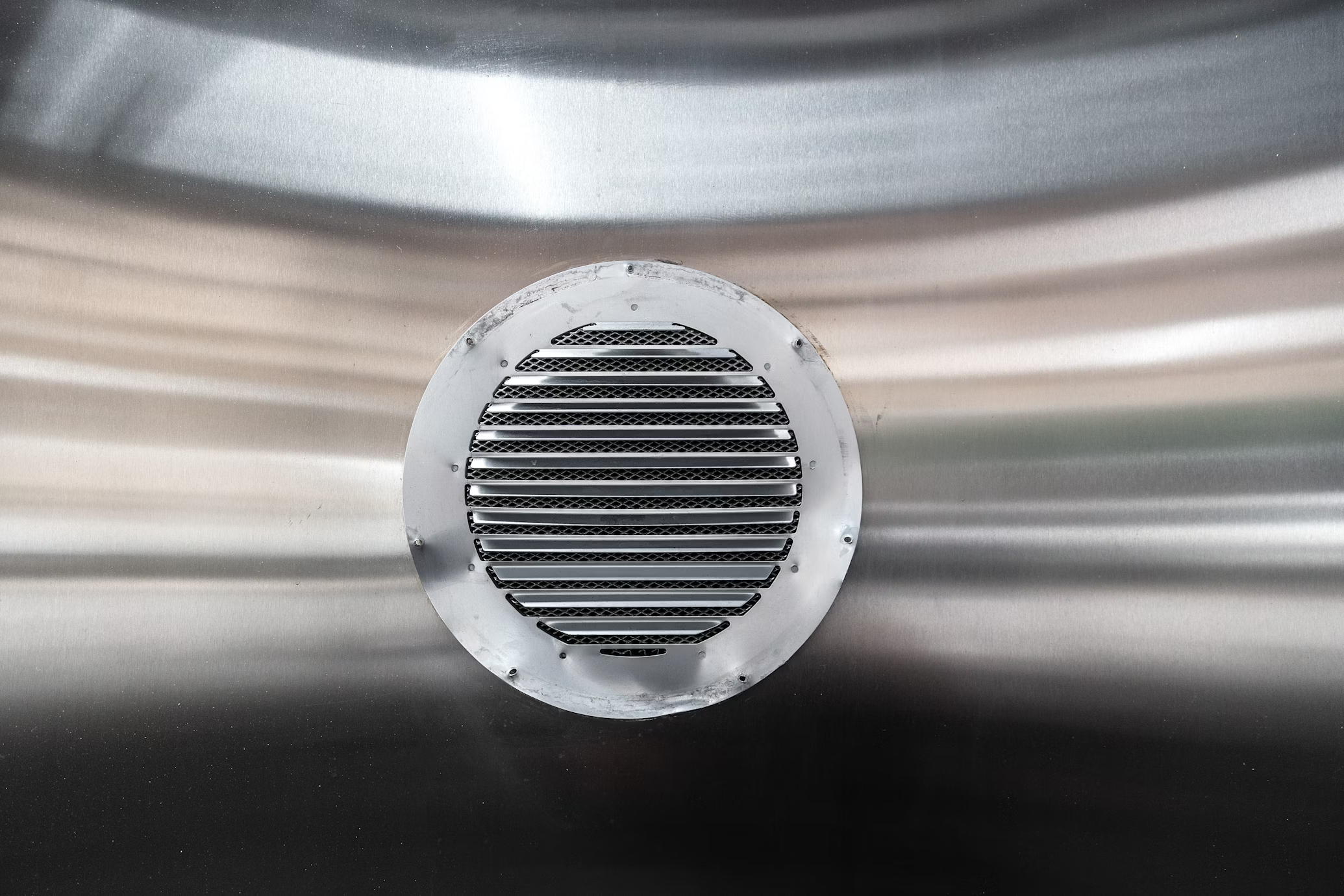

Passive vents are the simplest and most budget-friendly option for ventilating a shipping container. They rely on natural airflow to keep the interior fresh.

- Best For: Storage containers and spaces with minimal ventilation needs.

- How It Works: Strategically place the vents on opposite walls or ends of the container to promote cross-ventilation. Fresh air flows in from one side, pushing stale air out the other.

- Advantages: Affordable, easy to install, and requires no electricity.

- Drawbacks: Less effective in extreme climates and may not completely prevent condensation in humid areas.

Passive vents are great for basic storage containers, where the primary goal is to prevent moisture buildup and heat retention.

Foundation Vents: Cool Air from the Ground Up

Foundation vents are located on the walls directly above the floor so that the container’s lower parts can have ideal airflow. These vents are particularly effective when combined with upper vents to create a natural convection cycle.

- Best For: Elevated containers, especially in hot climates.

- How It Works: Cool air enters through the foundation vents while warm air escapes through vents higher up.

- Advantages: Helps regulate temperature and improves airflow naturally.

- Drawbacks: Foundation vents need to be paired with other types of vents for optimal performance. They may also require screening to keep pests out.

For containers placed on blocks or raised foundations, this option is an easy way to introduce cooler air into the space.

Solar Vents: Green and Off-Grid Friendly

Solar vents use solar energy to power a fan, providing active ventilation without relying on traditional electricity.

- Best For: Off-grid locations or eco-friendly projects.

- How It Works: A small solar panel collects sunlight to power the fan, which circulates air inside the container.

- Advantages: Sustainable, cost-effective in the long run, and ideal for sunny areas.

- Drawbacks: Less effective on cloudy days or in areas with limited sunlight.

These vents are perfect for containers in remote locations or for those looking to reduce their carbon footprint.

Turbine Vents: Harnessing Wind Power

Sometimes known as whirlybird vents, this vent uses wind power to draw hot air out of the container and keep the container cool.

- Best For: Windy locations or spaces where heat removal is a top priority.

- How It Works: The spinning turbine creates a suction effect, pulling hot air out of the container.

- Advantages: No electricity required and highly effective in windy areas.

- Drawbacks: Ineffective in areas with little wind and may not address moisture issues on their own.

Turbine vents are a cost-effective solution for containers in consistently breezy regions.

How to Install the Vents

Once you’ve chosen the right type of vent, it’s time to install it by following the steps on how to vent a shipping container.

Plan Your Vent Placement

Decide where each vent will go based on your container’s airflow needs. Think about cross-ventilation, heat removal, and potential moisture issues that can impact the container’s integrity.

Gather Your Tools and Materials

You’ll need:

- Vents (passive, active, or solar)

- A power drill with metal-cutting bits

- A jigsaw or reciprocating saw

- Screws, bolts, or welding tools

- Sealant to prevent leaks

Cut the Holes

- Use a pencil or chalk to mark the vent’s intended spot.

- Drill a pilot hole to guide your cutting.

- Use a jigsaw or saw to cut the required openings for your vents.

Secure the Vents

- Position the vent and secure it with screws, bolts, or welds.

- Use sealant around the vent to keep water and other debris from seeping in.

Test the Ventilation

Once installed, check the airflow to ensure the vents are working as expected. Adjust or add more vents if necessary.

Perform Regular Maintenance

To keep your ventilation system effective, clean the vents periodically and inspect them for damage, rust, or debris.

Vent Cleaning Tips

While knowing how to vent a shipping container is important, occasional ventilation system cleaning is also important to keep debris from piling up. Check out the following tips to clean the vent when it’s time.

- Inspect Regularly: Schedule periodic inspections, especially if you use the container in dusty or humid environments. Look for blockages, debris, or signs of rust.

- Remove Debris: Use a soft brush or compressed air to clear dirt, dust, and cobwebs from the vent openings. For stubborn grime, gently scrub with a damp cloth and mild soap.

- Check for Rust: Steel vents are prone to rust over time. If you notice rust spots, use sandpaper or a wire brush to clean them off. Apply a rust-proof primer and paint to prevent further damage.

- Ensure Screens Are Intact: Many vents have screens to keep out insects and small animals. Check for tears or holes and replace damaged screens promptly.

- Clean Filters (If Applicable): If your vent system has filters, clean or replace them according to the manufacturer’s guidelines.

- Reapply Sealant: Inspect the sealant around the vents for cracks or wear. Reapply sealant to ensure a watertight seal.

Regular cleaning keeps your container’s vents working efficiently, prolonging their lifespan and ensuring a healthy indoor environment.

Conclusion

By knowing how to vent a shipping container properly, we can rest easy knowing that our belongings or cargo won’t become damaged from bad airflow. If you need a container flexible enough for all ventilation customizations, look no further than Tradecorp! With products ranging from the 45′ HC SO DD Insulated Container already available with custom vents to other containers, Tradecorp prioritizes customizability in all its lineups. Order today via our quote form!