The flexibility for the use of sea container products needs no introduction. Shipping containers, as we know, are the most widely used platform for carrying numerous cargo with different handling protocols.

However, places like oil rigs and similar offshore sites pose more pressing challenges. Unlike the more common land-based construction sites and storage facilities with stable positioning, oil rigs must use numerous stabilizing means to stay afloat.

As a result, using and loading regular shipping containers in these sites can be difficult. Apart from the harsh sea waves, salt content from the speedy winds can pose considerable damage to any steel-based construction.

Also Read: Cut Container Shipping Costs with the Best Practices

Challenges of Working in Oil Rigs

When it comes to working in oil rigs, companies must pay attention to numerous technical challenges often not found in other workplaces.

Regulatory Compliance

Health and safety guidelines and operational standards are some things all oil rig workers must abide by when working. This is particularly true when loading a sea container carry cargo worth thousands or millions of dollars.

Worker Safety

Accidents and injuries when operating heavy machinery or loading a sea container in an oil rig are unfortunately common risks. As such, the oil rig management must employ strict means to keep their workers safe when working.

Equipment Maintenance

Constant exposure to rust-causing saltwater, harsh winds, and heavy rains can damage both the oil rig’s equipment and the shipping containers it uses. Proper maintenance protocols must be followed to protect them from damage that can downgrade their usability.

Environmental Hazards

Being structures constructed in the middle of open, high seas, phenomena including storms, hurricanes, and tall waves are common. Since they can significantly threaten oil rig operations, workers must know when not to load shipping containers when these weather conditions happen.

Logistical Challenges

The oft-remote locations of oil rigs mean it is common for companies to use shipping containers to bring equipment and supplies there. As a result, shipping containers used for this purpose should be tailor-made for offshore operations.

Containers Suitable for Oil Rigs and Offshore Sites

While most shipping containers are designed for general purposes across various industries, their performance can be insufficient in certain places like oil rigs.

The problem lies in the design and construction. While manufacturers like Tradecorp design their standard shipping containers to withstand maritime freight, their specifications do not count for prolonged use in oil rigs and offshore sites.

For that reason, Tradecorp designs more tailor-made sea container products that can handle long-term use in oil rigs. While looking nearly similar to regular containers, these offshore DNV containers function specifically to help oil rig workers handle cargo-related matters in their workplaces.

Short for Det Norske Veritas, DNV containers are certified by the DNV classification society so they can function as shipping containers for the oil and gas industry.

Then what differentiates a DNV sea container from its standard counterpart?

Unmatched Safety Standards

Safety is paramount in offshore environments, where workers are exposed to extreme weather, rough seas, and potentially hazardous conditions. DNV containers are built to meet the highest safety standards, ensuring they can withstand the rigors of offshore use.

They are designed with reinforced structures, anti-slip flooring, and corner castings to handle rough handling and secure stacking on moving platforms. Additionally, DNV containers often come equipped with fire-resistant materials, pressure relief valves, and other safety features tailored to offshore environments.

Versatility in Applications

Oil rig workers can use DNV containers to store tools, equipment, and supplies and transport critical materials to and from the rigs. This versatility ensures that offshore teams have access to well-organized, secure spaces that improve productivity and efficiency.

Durability in Harsh Environments

One of the most well-known features of DNV containers is their durability. Offshore environments are notoriously tough, with exposure to saltwater, high humidity, and fluctuating temperatures that can quickly degrade standard equipment.

DNV containers are specifically engineered to resist these elements. Constructed with high-grade steel and coated with anti-corrosion paint, these containers maintain their integrity even in the harshest conditions.

This durability results in lower maintenance and replacement costs, ensuring that the containers remain reliable assets for years.

Meeting Industry Standards and Compliance

Other than their practical benefits, DNV containers ensure compliance with the strict regulations governing offshore operations.

These containers are certified according to DNV 2.7-1 or similar standards, which verify their safety, strength, and suitability for offshore use.

By using DNV-certified containers, companies can demonstrate their commitment to the industry’s best practices, protect their workers, and minimize liability.

Examples of DNV Containers

While knowing the benefits of a DNV sea container is important, knowing how a DNV container looks is just as important for your knowledge.

2M Tool Box DNV Offshore Container

Tradecorp’s 6’7″ (2m) Toolbox, or the 2M Tool Box DNV Shipping Container, is a unique solution to meet the particular storage requirements of tools and equipment used in offshore activities. Expertly designed while adhering to the strictest industry standards, this DNV sea container blends durability and functionality.

The container’s 45° sling angle is a notable feature that increases its adaptability in lifting and shipping cargo. This angle ensures the container can be easily used in many logistical processes by optimizing its stability and load distribution.

4′ x 4′ x 3′ Basket Offshore DNV

With many internal lashing rings for cargo security, this 4′ x 4′ x 3′ Basket Offshore DNV container can reduce the possibility of damage and accidental movement. It has pad eyes for safe lifting and has a special stackable construction to conserve room.

The container’s stackable design maximizes the limited deck area and guarantees effective cargo storage during operations while the rig is unused. Furthermore, all of its units come with slings, shackles, and forklift compartments.

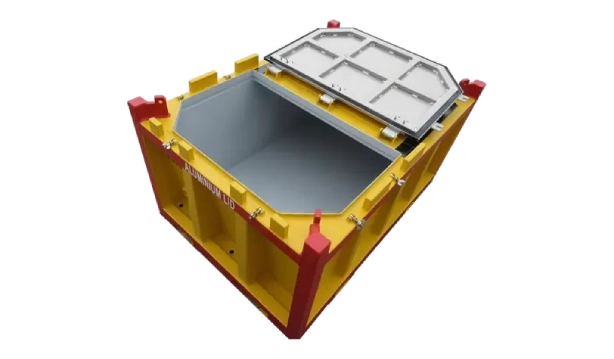

7’10 5’7 4’2 Cutting Skip Offshore DNV Container

The 7’10 5’7 4’2 Cutting Skip Offshore DNV Container is ideal for offshore cutting waste transport requirements since it has a rubber-sealed top hatch, pad eyes, external lashing rings, forklift pockets, and full penetration welding. Additionally, it features a rubber-sealed top hatch that offers superior defense against dust and moisture.

Additionally, the container has pad eyes, which offer extra support when being lifted and transported. Thanks to the external lashing rings on the container, your cutting waste will stay in place and not endanger other cargo or crew members.

10′ Lifting Frame Offshore DNV

This 10′ Lifting Frame Offshore DNV container is designed for heavy loads that don’t require extra weather protection. It satisfies the DNV 2.7-1 standard and ensures robustness in challenging offshore conditions.

Furthermore, it can effectively move and store supplies and equipment in its capacity as a Cargo Carrying Unit (CCU). To facilitate cargo handling, the container also incorporates external lashing rings, lateral supports, and internal lashing points.

20′ Offshore Test Cabin

This 20-foot DNV shipping container with a test cabin is perfect for testing operations in offshore oil rigs. Staff can easily enter the container thanks to the personnel door attached to the easy-open door.

These containers are the best option for companies that deal with flammable gasses, dust, and vapors. All this is possible because they have safety features including explosion-proof electrical installations, protective bars on windows and doors, and fully insulated interiors.

Also Read: Shipping Container Storage Units: How to Maintain Them

Conclusion

Since its specifically designed construction can withstand the rigors of offshore operations, nothing is better than a DNV sea container to do the job. If you need one to help with your project, contact Tradecorp today via its quote form to buy or rent one! With its considerable product catalog, Tradecorp guarantees maximum convenience and efficiency for all its customers.