As 2025 progresses, many supply chain disruptions caused by numerous factors will continue impacting the industry’s operations.

These disruptions mean organizations must prepare for a volatile and uncertain landscape, including geopolitical tensions, climate change, cybersecurity threats, and labor shortages.

Also Read: Potential Cold Chain Trends in 2025 and What to Expect

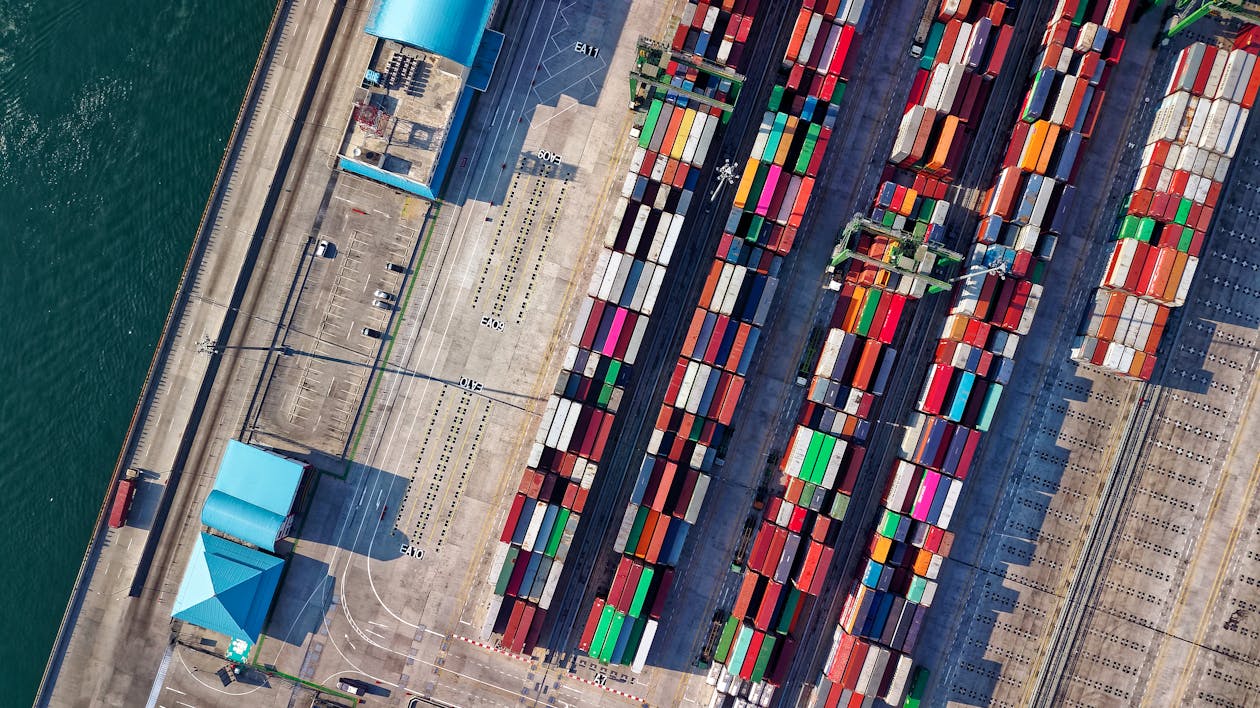

Supply Chain Disruptions in 2025

In this opportunity, Tradecorp will break down some supply chain disruptions that can impact the industry in 2025 to help stakeholders prepare.

Geopolitical Tensions Reshaping Trade Routes

Geopolitical instability is still one of the most pressing concerns for global supply chains in 2025. The United Nations reported that 2023 witnessed more violent conflicts globally than any period since World War II.

As a result, 110 million people must flee their homes due to danger, fighting, or severe societal disruptions, and this trend shows little sign of abating.

Trade routes face particular vulnerability, with ongoing conflicts creating bottlenecks in critical maritime passages.

The Red Sea crisis is an example of this trend, where vessels must reroute around the Cape of Good Hope which delays transit times and increases costs.

Trade policies will likely undergo rapid and unpredictable changes in response to shifting diplomatic relations.

New tariffs, sanctions, and export restrictions will complicate international commerce, requiring supply chain managers to monitor regulatory developments and adjust strategies accordingly.

Climate Change and Extreme Weather Events

Climate-related disruptions will intensify in 2025, earning a 90% risk score from analysts who track supply chain threats.

A study published in Nature Sustainability predicts that weather-induced supply chain disruptions will increase significantly over the next 15 years.

These events range from acute disasters like hurricanes and floods to chronic stresses such as changing rainfall patterns and rising temperatures.

Agricultural supply chains face particular vulnerability as climate change alters growing conditions for key crops.

Shifting precipitation patterns will disrupt traditional harvesting schedules, while extreme heat can damage transportation infrastructure, including buckling railways and softening asphalt roads.

Port facilities worldwide remain susceptible to rising sea levels and storm surges, threatening critical nodes in global logistics networks.

Meanwhile, manufacturing operations will encounter increasing pressure to adapt to climate realities.

Water-intensive industries may struggle in regions experiencing prolonged drought, while facilities in coastal areas must contend with flooding risks.

Digital Threats to Supply Chain Security

Cybersecurity threats will evolve significantly in 2025, with analysts assigning a 75% risk score to these digital dangers.

Interconnected supply chains create expanded attack surfaces for malicious actors, with the greatest vulnerabilities often residing with smaller, less-secured suppliers.

According to security experts, the biggest cyberattack risks in 2025 will most likely originate with sub-tier suppliers, where criminals can more easily exploit vulnerabilities before working their way up to Tier 1 suppliers through software and network connections.

This chain-based vulnerability requires comprehensive security frameworks that extend protection beyond organizational boundaries.

Supply chain systems now incorporate increasing levels of automation and digital control, making them attractive targets for ransomware attacks that can halt operations entirely.

A single cyberattack on a major logistics provider could disrupt the global flow of goods, halting production lines and emptying shelves overnight.

This scenario highlights the need for robust cybersecurity measures, regular vulnerability assessments, and incident response planning across all supply chain participants.

Critical Resource Scarcity

Access to rare metals and minerals will become increasingly problematic in 2025, with analysts assigning a 65% risk score to this challenge.

These resources prove essential for advanced technologies, renewable energy systems, and everyday consumer electronics, yet their supply faces constraints from both geological and geopolitical factors.

Extraction of these critical materials often occurs in politically unstable regions or concentrates in a handful of countries, creating vulnerability to supply disruptions.

Competition for these limited resources will intensify as more industries transition to green technologies and digital systems that require specific materials like lithium, cobalt, and rare earth elements.

Price volatility will likely increase throughout 2025, complicating cost forecasting and budget planning.

Organizations should explore alternative materials, invest in recycling initiatives, and secure long-term supply contracts to mitigate these risks.

Those who fail to address resource scarcity proactively may find themselves unable to maintain production schedules or forced to absorb significant cost increases.

Workforce and Labor Challenges

Labor issues will continue to plague supply chains in 2025, with aging workforces, skills gaps, and increased scrutiny of labor practices creating multifaceted challenges.

Key issues contributing to this problem include an aging workforce, a lack of skilled labor, and high turnover rates.

These factors create persistent staffing shortages across transportation, warehousing, and manufacturing operations.

Forced labor concerns will receive heightened attention, with analysts assigning a 60% risk score to crackdowns on exploitative labor practices.

Supply chain managers must increasingly verify ethical standards throughout their supplier networks, requiring enhanced visibility and verification processes that add complexity to operations.

The technological transformation of supply chains will simultaneously create new jobs while eliminating others, requiring workers to adapt to changing skill requirements.

Organizations that invest in training, knowledge transfer programs, and improved working conditions will gain an advantage in attracting and retaining talent during this transition period.

Technological Transformation as Both Solution and Challenge

Advanced technologies including artificial intelligence will help refine and optimize supply chains, providing tools to manage complexity and forecast disruptions.

AI-powered systems can analyze vast datasets to identify patterns, predict potential bottlenecks, and recommend alternative strategies before problems manifest.

However, technological implementation brings challenges. Data quality emerges as a critical concern, with the effectiveness of AI systems depending entirely on the accuracy and completeness of underlying information.

“Accuracy and reliability of source data are key to the outputs produced via artificial intelligence. As more companies adopt AI automation to streamline processes, obtaining accurate, timely data across their supply chain remains daunting,” note industry observers.

Organizations must balance automation with human expertise, ensuring technological systems enhance rather than replace critical thinking and decision-making.

The most successful implementations will combine AI capabilities with experienced supply chain professionals who can interpret results and apply contextual understanding to complex situations.

Regulatory Compliance Complexity

The regulatory landscape will grow increasingly complex in 2025, with new international trade regulations, environmental reporting requirements, and traceability mandates creating administrative burdens.

Compliance automation will become essential as transport companies, especially those operating internationally, leverage AI tools to navigate varied regulations at every checkpoint.

Environmental, social, and governance (ESG) considerations will receive particular attention, with stakeholders demanding transparent reporting on sustainability metrics throughout supply chains.

These requirements will necessitate enhanced data collection and verification processes, adding layers of complexity to already intricate operations.

The cost of compliance will increase accordingly, requiring organizations to balance regulatory requirements with operational efficiency.

Those who develop streamlined compliance systems may find a competitive advantage through reduced administrative costs and decreased risk of penalties or operational disruptions due to regulatory issues.

Also Read: Global Shipping Industry Updates: January-February 2025 Trends

Conclusion

With a better understanding of supply chain disruptions that can keep impacting the industry in 2025, stakeholders can become more prepared to face them. To ensure your cargo’s utmost safety during freight, trust no other solution than Tradecorp! With its vast catalog of shipping containers made from the most durable materials, Tradecorp’s containers will keep your cargo safe. Order one today!