Once you’ve turned a shipping container into a comprehensive storage platform, it needs a proper container venting system that filters air.

Whether you used a container as a storage platform for intermodal transport or a permanently installed storage shed, it still needs a vent.

Last time, we explained the venting system for shipping containers and their types. This time, we’ll explain how to clean the vents so they can keep filtering the storage’s airflow!

Also Read: How To Vent A Shipping Container: The Ultimate Know-How

Brief Outlook on Standard Container Venting Systems

For starters, several container venting system types filter air based on their design complexity and specifications.

Air vents, often found along the sides or near the top corners, promote basic air circulation. Louvered vents offer adjustable airflow control while preventing water ingress.

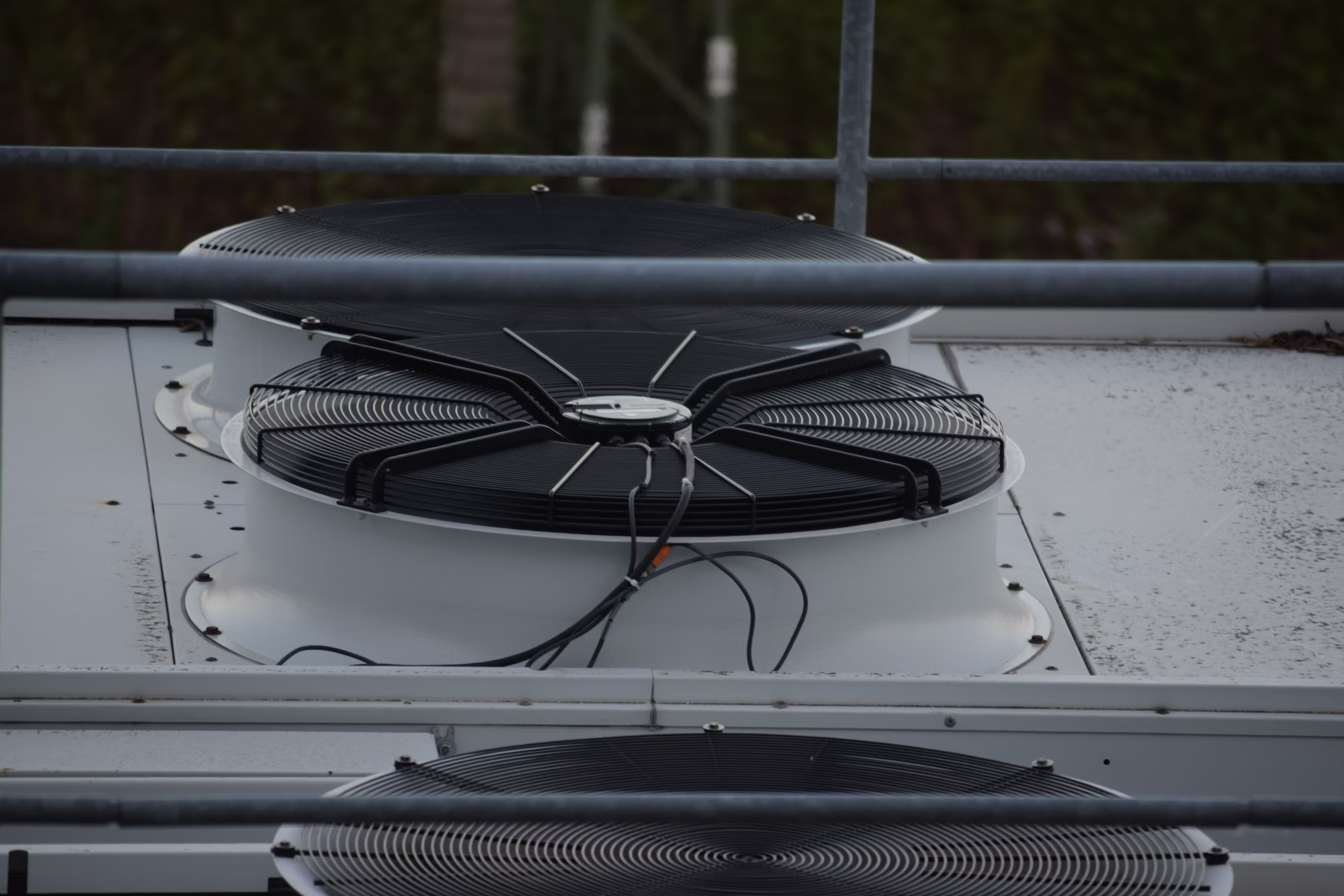

Whirlybirds, or turbine vents, utilize wind power to actively extract air from the container.

Shutter exhaust vents allow air to exit the container while preventing backflow. Meanwhile, solar vents employ solar energy to power fans that circulate air.

Air vents in containers are typically passive ventilation solutions that allow air to flow in and out of the container naturally.

Understanding these vent types is crucial for effective maintenance. Each type requires different cleaning techniques and schedules based on its design and location on the container.

Why Cleaning Shipping Container Venting is Important

Cleaning the venting systems of shipping containers carries significant importance for several reasons.

Vents promote airflow, preventing the accumulation of moisture, condensation, and stagnant air. Regular cleaning ensures that these vents function optimally, maintaining proper ventilation and minimizing the risk of damage to stored items.

Blocked or dirty vents can lead to increased humidity levels, fostering mold and mildew growth, which can damage stored goods and create unpleasant odors.

Effective ventilation helps regulate temperature, preventing excessive heat buildup that could damage sensitive materials.

For instance, items like electronics or documents can be particularly susceptible to heat damage if not properly ventilated.

Moreover, clean vents contribute to better air quality inside the container, reducing the risk of corrosion and preserving the structural integrity of the container itself.

In addition, regular cleaning also ensures that any pests or insects do not find a breeding ground within your shipping container.

Debris accumulation can attract unwanted pests that may compromise both your belongings and the container’s structure over time.

By keeping vents clean and unobstructed, you create an inhospitable environment for pests while promoting a healthier storage space.

Consistent cleaning helps prevent the accumulation of debris, dust, and other contaminants that can impede airflow and reduce vent efficiency.

How to Clean Container Venting Systems

Maintaining clean and efficient venting systems requires a systematic approach tailored to each vent type. Here’s how to do each container venting type:

Air Vents

Air vents are commonly located on the sides or near the top corners of shipping containers and facilitate basic air circulation.

- Inspection: Begin by visually inspecting the air vents for any signs of blockage, such as dust, debris, leaves, or insects.

- Dry Cleaning: Use a stiff brush or vacuum cleaner with a narrow attachment to remove loose dirt and debris from the vent openings and surrounding areas.

- Washing: Prepare a solution of mild detergent and warm water. Use a sponge or soft brush to gently scrub the vent covers and surrounding surfaces.

- Rinsing: Rinse thoroughly with clean water to remove any soap residue using a low-pressure hose.

- Drying: Allow the vents to dry completely before closing the container. Ensure no moisture remains as this can promote mold growth.

- Maintenance: Regularly check the vents for rust or damage and treat any rust spots with a rust converter or rust-inhibiting paint.

Louvered Vents

Louvered vents feature angled slats that allow airflow while preventing rainwater from entering the container.

- Inspection: Check the louvered vents for any obstructions like dirt, leaves, or nests.

- Dry Cleaning: Use a brush or vacuum cleaner with a narrow attachment to remove loose debris from between the slats.

- Washing: Prepare a mild detergent solution and use a sponge or cloth to gently wash the louvers’ surfaces.

- Detailed Cleaning: For hard-to-reach areas between slats, use a small brush or cotton swab to sweep them.

- Rinsing: Rinse thoroughly with clean water and ensure no soap residue remains.

- Drying: Allow louvers to air dry completely and use a dry cloth if necessary.

- Adjustment: Check adjustability and ensure the louvers move freely by lubricating stiff mechanisms with a silicone-based lubricant.

Whirlybirds (Turbine Vents)

Whirlybirds utilize wind power to actively extract air from the container enhancing ventilation.

- Inspection: Inspect the whirlybird for signs of damage like bent blades or rust.

- Safety Precautions: Ensure the turbine is stationary before cleaning.

- Dry Cleaning: Use a brush or vacuum cleaner to remove dirt from blades and housing.

- Washing: Prepare a mild detergent solution and wash the turbine blades and housing gently.

- Rinsing: Rinse thoroughly with clean water using a low-pressure hose if needed.

- Lubrication: Apply silicone-based lubricant to moving parts ensuring smooth operation.

- Testing: After cleaning, check if the turbine spins freely with a slight breeze and inspect any remaining obstruction if it’s not functioning.

Shutter Exhaust Vents

Shutter exhaust vents allow air to exit while preventing backflow often used in combination with other ventilation methods.

- Inspection: Check shutter vents for signs of obstruction such as dirt or insects.

- Dry Cleaning: Use a brush or vacuum cleaner to remove loose dirt from openings.

- Washing: Prepare a mild detergent solution and scrub the vent covers gently to remove any grime.

- Rinsing: Rinse thoroughly with clean water ensuring no soap residue remains.

- Functionality Check: Ensure the shutters open/close freely and apply silicone-based lubricant if they stick.

- Drying: Allow vents to air dry completely before closing the container.

- Maintenance: Regularly check for damage or corrosion and repair/replace damaged components as needed.

Solar Vents

Solar vents utilize solar energy to power fans that circulate air inside providing continuous ventilation.

- Inspection: Inspect the solar panel for dirt blocking sunlight and check the fan for obstructions/damage.

- Cleaning Solar Panel: Use a soft cloth/sponge to gently wipe the surface and avoid harsh chemicals/scratches.

- Fan Maintenance: Check the fan blades for dirt/debris and clean them with a soft brush/cloth.

- Functionality Check: Ensure the fan operates smoothly when exposed to sunlight and troubleshoot wiring/connections if not working.

- Battery Maintenance: If the solar vent includes battery backup, check its condition/replace it per guidelines.

- Securing Connections: Ensure electrical connections are secure/corrosion-free and use corrosion inhibitors on exposed metal parts.

By following these detailed steps for each type of vent, you can provide optimal storage conditions while protecting your valuable contents.

Additional Container Venting Maintenance Tips

In addition to the regular cleaning routines outlined above, we have some additional maintenance tips that can further enhance your shipping container’s ventilation system:

- Seasonal Checks: Conduct seasonal checks on all ventilation systems before extreme weather conditions set in (e.g., heavy rains or winter snow). This proactive approach helps identify potential issues early on before they escalate into significant problems.

- Debris Management: Keep surrounding areas clear of debris such as leaves or branches that might block airflow into your shipping container’s ventilation system.

- Pest Control: Implement pest control measures around your shipping containers since pests can enter through uncleaned vents.

- Documentation: Maintain records of all inspections/cleanings performed on your shipping container’s ventilation systems so you can track maintenance history effectively over time.

- Professional Help: If you encounter persistent issues with your ventilation system despite regular maintenance efforts, consider consulting professionals who specialize in shipping container maintenance services.

Also Read: Shipping Container House Plans Examples and Breakdowns

Conclusion

So long as you follow the best container venting cleaning methods regularly, your storage will always have the best airflow and be safe from stale airflow-related damage. If you need a shipping container that can fit all the container venting types above, buy or rent one from Tradecorp! Designed with the best specifications and materials, these containers are known as industry-leading products. Order one today!