When you want to ensure your shipping containers have good airflow in any situation, reading into some shipping container venting FAQs can help you handle that situation.

By following these FAQs, you can choose the ventilation option you need to improve your shipping container or modular building’s usefulness and performance.

Without further ado, check these shipping container venting FAQs for your convenience!

Also Read: Container Venting System Cleaning and How to Do It

Shipping Container Venting FAQs

Why do I need to ventilate my shipping container or modular building?

Shipping containers are designed to be airtight for ocean transport, which is great for keeping out seawater but not so great for long-term storage or habitation.

Without proper ventilation, you can expect these problems to occur in your containers soon:

- Mold and mildew: Moisture builds up inside and creates the perfect environment for mold growth.

- Rust and corrosion: Condensation can form on the steel walls and eat away at your container and anything metal inside.

- Bad odors: Stale air and excess moisture can make your container smell musty.

- Health risks: Poor air quality can cause respiratory problems and other health issues, especially in container homes or offices.

What are the main types of ventilation for containers?

There are two primary container venting categories you must know for improving your container and modular buildings:

Passive Ventilation

- How it works: Uses vents, windows, or other openings to let air naturally flow in and out, usually by wind or temperature differences.

- Common types: Side/louvered vents, ridge vents, foundation vents, and openable windows/doors.

- Best for: Simple storage, mild climates, or as a supplement to mechanical systems.

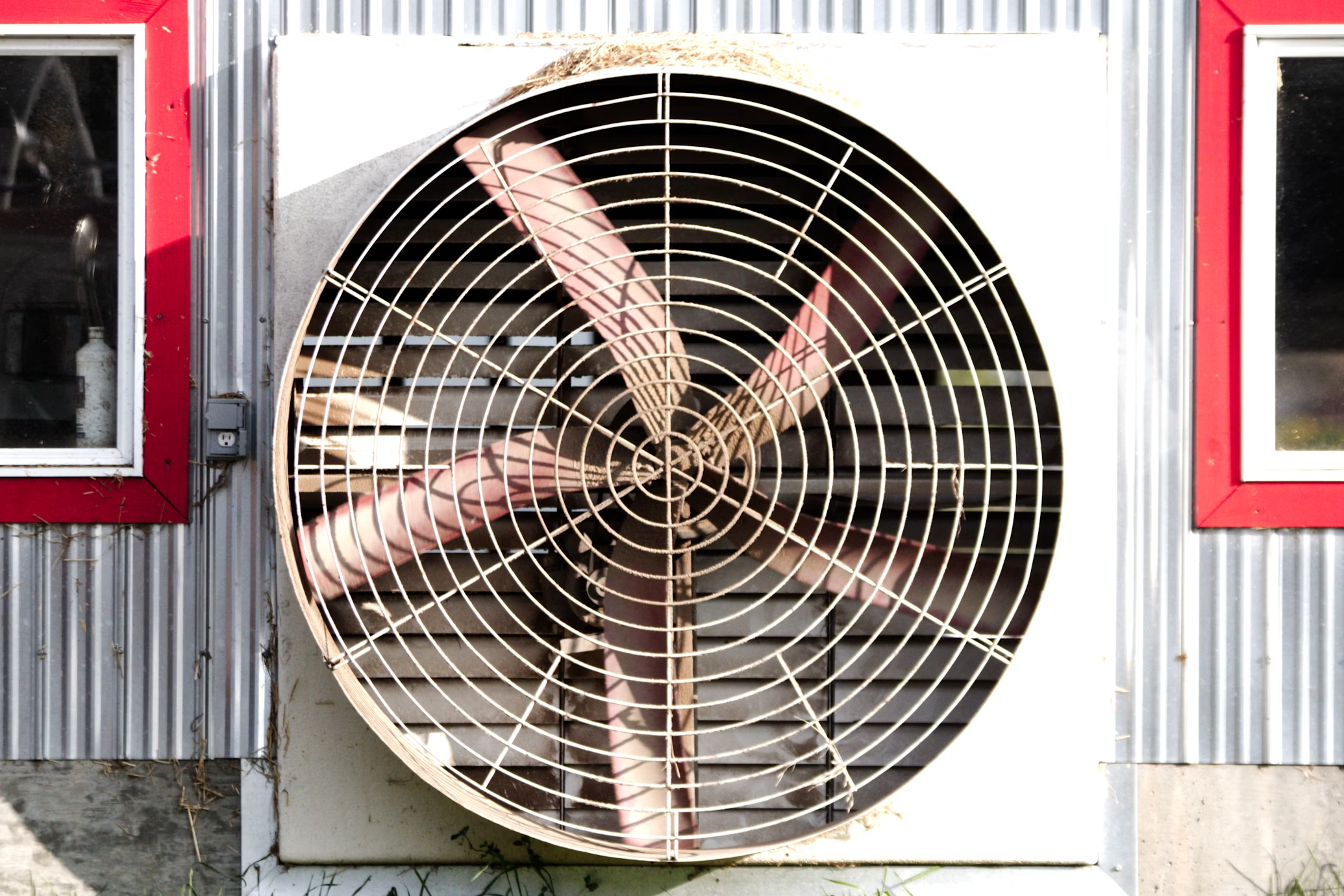

Mechanical (Active) Ventilation

- How it works: Uses fans or powered systems to move air in and out, regardless of outside conditions.

- Common types: Extractor (exhaust) fans, supply fans, balanced systems (both supply and exhaust), and heat recovery ventilators (HRVs).

- Best for: Container homes, offices, bathrooms, kitchens, or any space with people, electronics, or moisture-producing activities.

How does cross ventilation work in a container?

Cross ventilation is the simplest and most cost-effective method, where you install vents or windows on opposite sides of the container so that wind can blow air in one side and out the other.

With this cross ventilation, you can create a breeze that flushes out hot, humid, or stale air and brings in fresh air.

Pro tip: Place one vent high and one low, or use windows just under the roof for better airflow. The bigger and more strategically placed the openings, the better the air movement.

What’s the difference between side vents and roof vents?

- Side vents (louvered): Cheaper and easier to install, you can place these vents diagonally (one high, one low) for cross ventilation.

- Roof vents (turbine or ridge): Turbine vents use wind to spin and suck air out, while ridge vents let hot air escape passively from the highest point.

When do I need mechanical ventilation?

If you’re using your container as a home, office, bathroom, or for sensitive equipment (like data centers), passive vents alone usually aren’t enough.

Mechanical ventilation is a must in these cases, so use extractor fans, supply fans, or balanced systems can keep air fresh and humidity under control.

What is a balanced ventilation system?

A balanced system uses both supply and exhaust fans to bring in fresh air and remove stale air at the same rate.

This keeps the air pressure inside the container stable, which is great for preventing dust, pollen, and outside odors from sneaking in.

Balanced systems are ideal for container homes and offices because they provide consistent, controlled airflow in all climates.

What about heat recovery ventilators (HRVs)?

HRVs are mechanical systems that exchange stale indoor air for fresh outdoor air while capturing most of the heat from the outgoing air.

They also help control humidity and improve energy efficiency, making them perfect for container homes in any geographical setting.

How do I ventilate a container bathroom or kitchen?

Bathrooms and kitchens produce a lot of moisture and odors, so you’ll want to install extractor (active) fans, just like in a regular home.

For bathrooms, you might need multiple vents if the space is large or includes showers, while you need range hoods and plumbing vents are essential to remove steam, smoke, and sewer gases in kitchens.

What are foundation vents, and when should I use them?

Foundation vents are passive vents installed just above the container floor, great for containers raised off the ground (on piers, beams, or blocks), and help airflow along the bottom.

However, you shouldn’t use them if your container sits on a slab foundation, as water can pool and enter the container.

How many vents do I need, and where should I put them?

The number and placement of vents depend on your container’s size, use, and climate:

- For a 20-foot container, 4×4” vents on opposite walls are a good start.

- For a 40-foot container, 6×6” vents work well.

- Place vents high for hot air escape and low for cooler air intake.

- For best results, use pairs of vents on opposite sides for cross ventilation.

If you’re in a hot, humid, or tightly sealed environment, add mechanical fans or HRVs that can handle such environments.

Can I just open the doors or windows for ventilation?

Yes, opening doors and windows is the simplest way to get fresh air. However, it’s not always practical (for security, weather, or privacy reasons), and it doesn’t provide continuous airflow.

Permanent vents or fans are better for consistent, reliable ventilation, making them important for almost all shipping containers and container modular buildings.

What problems can poor ventilation cause?

- Mold and mildew growth

- Rust and corrosion

- Musty odors

- Condensation on walls and the ceiling

- Health issues (allergies, asthma, respiratory problems)

- Damaged goods or equipment

Are there any special accessories I should consider?

- Dehumidifiers: Great for reducing moisture, especially in humid climates or for storing sensitive items.

- Air filters: Help keep dust and pollutants out, especially in supply-only or balanced mechanical systems.

- Airtight dampers: Prevent outside air from entering when vents aren’t in use, improving energy efficiency.

Do I need insulation with my ventilation?

Absolutely! Insulation helps control temperature and prevents condensation inside your container.

Spray foam insulation is popular for its high R-value and moisture barrier properties, but batt insulation can also work well.

Can I install vents myself, or should I hire a pro?

If you’re handy, installing passive vents is a straightforward DIY project.

Mechanical systems (fans, HRVs, complex ducting) might require professional installation, especially if you need electrical work or want to ensure airtightness and efficiency.

Also Read: Container Home Foundation: Importance, Components, and Types

Conclusion

By learning through the shipping container venting FAQs above, you can choose which venting you must use for your container. To ensure the container is ready for use by default, contact Tradecorp today! With the company’s trusted container lineups, you’ll find the one you need to handle all your container-related needs.